Cut-To-Length / Multi-Blanking Lines

September 21, 2018CHAMPAGNE METALS

Champagne Metals is an aluminum service center and processor that has been in business for 25 years. They are headquartered in Glenpool, Oklahoma, and also have facilities in Lebanon, Missouri, and Middlebury, Indiana. They serve all of North America, mostly in the automotive and industrial markets. Champagne Metals was looking to expand their capabilities, specifically in the blanking industry.

Since they do not process standard material day in and day out, Red Bud Industries’ ability to customize a coil processing line to their exact specifications and needs was very important to them. They also needed a vendor that they could trust to stand behind their machinery after the sale, and Red Bud delivered.

“Red Bud’s service has been fantastic. They have been veryresponsive anytime we call. Their hotline is there for any type of issue that we have, and they can log in and tell us what to do to it. . . We are absolutely satisfied with the way the line is running, and we would definitely look to do future business with Red Bud.”

-Burns Getchell, General Manager, Champagne Metals

Read More Watch VideoWIELAND METAL SERVICES

Prior to the purchase of their Red Bud Industries Multi-Blanking Line, Wieland Metal Services used multiple coil processing lines to create their customers desired end product.

“We were able to condense two cut-to-length lines with the Red Bud Line. It opened up space in our facility and increased production and efficiency. If you are looking for a highly capable, safe machine, if you are looking for throughput, and a quality product, then I would truly recommend Red Bud.”

– Bhoopendra “Navin” Sukhraj

Read More Watch VideoCOIL STEEL PROCESSING

Red Bud’s Stretcher Leveler was exactly what Coil Steel Processing was looking for. Red Bud’s outstanding reputation for customer service and dedication to their customers made their choice easy. While the purchase of the new Cut-To-Length Line was going to expand their business, Coil Steel Processing knew that they also needed to improve the layout of their building.

“We could not be happier that we chose Red Bud. They have had a dramatic impact on our customers and our business.”

– Kevin Friedman, President

Read More Watch VideoMAGNA STAINLESS

“Red Bud stood out to Magna Stainless. Their service, support, and after sales service had a very good reputation. Red Bud is the leader in design and manufacture of Coil Processing Lines. They are able to offer an innovative, robust design that will always work and never let you down.”

-Nolan Mills, Operations Manager, Magna Stainless

Read More Watch VideoVALCOVNA PROFILOV

“One of the main advantages that Red Bud Industries gives us is 24/7 technical assistance that is on a very high level. Other companies in this business do not give us this high level of technical service. Based on our experience, we now decided to look for another cut-to-length line, of course, equipped with stretch level technology. And I am sure that Red Bud Industries will be one of the best suppliers of such equipment.”

-Vladimir Sumec, Valcovna Profilov

Read More Watch VideoBTH IMPORT STAL

BTH Import Stal has been an important supplier for the Polish steel industry for nearly three decades. They are among the largest domestic importers of stainless steel and have worked with the furniture, food, chemical, and other stainless steel industries.

Red Bud Industries was their first experience with coil steel processing. Red Bud’s advanced Multi-Blanking technology was important to BTH Import Stal in order to make 8 mults of stainless in one shearing cycle.

“We are processing 45,000 tons of stainless steel annually. Fortunately, Red Bud’s 24/7 hotline allows us to solve any problem that occurs within a few minutes. We are very satisfied with our purchase from Red Bud Industries, and I’m sure that our next purchase will also be from them.”

– Tomasz Kotarba, Member of the Board

Read More Watch VideoPETERSEN ALUMINUM

Quality and Value that Satisfies

“Red Bud…has put us in position to grow our market share faster than the growth of the construction industry. We have been very pleased with the results.”

[Mike Petersen, CEO, Petersen Aluminum]

The first Mike Petersen had ever heard of Red Bud was at a NAAD board meeting many years ago. He heard a couple board members mention Red Bud’s Cut-To-Length Lines. Today, he owns a number of them himself. Over the last several years, they were experiencing growing demand across their product line and knew they also needed more slitting capacity. Hoping to find a high quality, high speed Slitter that met their needs was the challenge. Frankly, they didn’t think such a product existed. Enter Red Bud.

They bought and installed the first Red Bud Slitter in their Acworth, Georgia, plant and have since installed similar lines in each of their five plants. We currently have nine Red Bud Lines in total, and we have been very pleased with the results.

Read MorePVS-METALS

Our Red Bud Industries’ Stretcher Leveler is so much more than an important piece of equipment– it has transformed our business.

When PVS-Metals, a subsidiary of Owen Industries, decided to expand into new markets, they turned to Red Bud Industries. Their investment in this new, massive Stretcher Leveler allowed PVS to reach into an entirely new marketplace offering the latest in Coil Leveling Technology. With this new expansion and dramatically improved automation and capabilities, PVS can handle any project from design to delivery, start to finish.

Red Bud’s ongoing dedication to manufacturing the most innovative, world class equipment in the industry clearly separates Red Bud Industries from the rest.

Read More Watch VideoMAGIC COIL PRODUCTS

Red Bud has been outstanding in response to training our employees as well as dedication to our customers’ needs and requirements. Red Bud Industries is a world class organization.

Magic Coil Products needed much more than a clever illusion to keep steel processing customers happy. They needed Red Bud’s Multi-Blanking Line – a Cut-To-Length Line with slitting capabilities that makes it easy and efficient to produce a custom size part. Now Magic Coil Products can produce tight tolerance blanks faster and more accurately and that makes both Magic Coil and their customers happy. No sleight of hand or magic wand–just smart solutions from Red Bud Industries!

Read More Watch VideoMCNEILUS STEEL, INC.

The products and services we provide make our customers more competitive. That’s what Red Bud does for us as well.

Our sheet and plate customers are competitive if their steel is “table top” flat and stays that way after processing. We once thought that meant a temper mill, but the Stretcher Leveler is a far better value. Today, we operate four Red Bud Stretcher Leveler CTL Lines at three facilities. We can supply a customer from any one of these facilities knowing they will get the same consistent, high quality product from those lines; just as Red Bud delivers the same consistent, high quality technology and support to us, day-in and day-out, year-after-year.

Read MoreRATNER STEEL SUPPLY

Customers choose us because our product is predictable, reliable, and repeatable. Same reasons we choose Red Bud.

We sell high quality cut sheet and plate our customers count on to stay at after lasering, forming, or whatever they do with it. Red Bud has the best technology for that, but execution really sets them apart. We operate two Red Bud Stretcher Leveler CTL Lines at our original facility, and decided to build a greenfield service center based around this advanced .500” Stretcher Leveler CTL Plate Line. We cut coil the same day we opened, and within just a few weeks, we were running 12 hours a day, 7 days a week, thanks to predictable, reliable, repeatable Red Bud support.

Read More Watch VideoMCNEILUS STEEL, INC.

Red Bud’s technology gave us a clear competitive advantage. Their service helps us maintain it.

At McNeilus Steel, we succeed by adapting to our customers needs. They needed ‘stay flat’ steel blanks, so we invested in a Red Bud Blanking Line with Stretcher Leveling. Our customers were delighted with the product, but also wanted it in heavier gage. We thought we‘d have to buy a temper mill, but Red Bud adapted to our needs and produced the first-ever .500” Stretcher Leveler CTL Plate Line. We were so pleased we bought two more. Not just because of the technology, but also because Red Bud supports us so well. They’re a customer first company.

Read MoreHIGH STEEL SERVICE CENTER LLC

Red Bud equipment and service gives us a competitive advantage our customers prefer.

The Dependability Difference® is High Steel Service Center’s commitment to provide value-added services and product innovations to support our customer’s success. Red Bud Industries plays a crucial role in meeting that commitment. Our HIGHSL® – Panel Flat that Stays Flat, 100% stress-free sheet and plate product is produced on a Red Bud Stretcher Leveler. We produce carbon, stainless, and aluminum leveled sheet and plate, multi-cut precision blanks, and slit coil – all on Red Bud equipment. Red Bud accuracy, reliability, and automation helps us deliver the highest quality material, on time, to keep our customers competitive.

Read MorePHOENIX METALS

Red Bud’s performance and reliability have been key to our growth. That goes for their equipment and their service.

I spec’d, bought and installed this Red Bud Multi-Blanking Line 15 years ago. The product coming off was of such quality and accuracy, it helped us win customers. Since then, we’ve added 7 more Red Bud Lines.

At Phoenix Metals, we are committed to fast turnaround of orders and we’ve built an infrastructure that allows us to do it. Our Red Bud Lines are dependable and they change over fast – they are key to our ability to respond. Just as important is Red Bud’s support. Many suppliers claim ‘24/7’ support. Red Bud actually delivers it.

Read MorePAUL BATTY, MIDWAY METALS

“We were looking for a new line to help better position ourselves in the market. We decided to go with Red Bud because of their reputation, service, and innovative designs. We felt their stretcher leveling technology would give us the opportunity to offer our customers a superior level of flatness. Now that the line is in, I have to say it performs as advertised. We have people that ask for our product due to the flatness we can produce and some customers have already told us they will not order from anywhere else.”

Read MoreGLENN SYLVESTER, MCNEILUS STEEL

“The new line really gives us an edge, our customers love the product!

We already had two Red Bud Stretchers at our Dodge Center facility so our customers were used to getting stretcher leveled material. So when we decided to get our own line, Red Bud was the obvious choice. We are very pleased with the new line, it has given us a real edge in our market. Our customers really appreciate the great quality and the flat product the line produces. With Red Bud, you don’t get any surprises, they do what they say. It’s quality equipment, great stuff!”

Read MoreDAVID BERNSTEIN, STATE STEEL SUPPLY COMPANY

“We were looking for a new Cut-To-Length Line for our Omaha facility. We had heard good things about Red Bud’s Stretcher Levelers, so we decided to take a look. We were impressed with what they offered, so we decided to buy one of their machines.

Now that the line is in operation, I have to say we are very happy with the system. The quality that comes off the line is exceptional. Our customers really like the product. Working with Red Bud was a positive experience. Their people were good to work with and they made sure the equipment went in without any hassles and was up and running quickly. The new line has lived up to our expectations. We are very happy with our decision.”

Read MoreAMIR YARI, PACKER YADPAZ PROFILES LTD

“As the thin gage, hot rolled market became more and more competitive in Israel, we realized that producing a “good” product was not enough. We wanted to separate ourselves from our competitors by being able to offer extremely flat, low stress material. After looking at our options, we decided that a Red Bud Line with a Stretcher Leveler would give us the capability to offer a product that no one else could match.

Now that our line is in operation, it is performing even better than we had expected. The Stretcher has lived up to its reputation. We are able to produce stress free material that stays flat even after secondary operations, no spring back! Laser cutters, in particular, have been enthusiastic about the product. Another of our goals was achieved by reducing the number of our shears, thanks to Red Bud’s Multi-Blanking System in our line.

The addition of Red Bud’s integrated line has not only increased our efficiency, but has given us a competitive advantage in our market at a time when every customer counts.”

Read MoreSCOTT SCHULTZ, PHOENIX METALS

“We’re Up To Seven And Counting

We bought our first line from Red Bud in 1997. At the time, we felt they offered the best capabilities and the most value for our money. Ultimately, their equipment proved to be a good value while providing superior performance. So, when we needed a second line, we went back to Red Bud. That has been several years ago, and today we are up to our seventh installation.

We have come to rely on Red Bud as they have become an integral part of our business. Our customers have come to expect a high quality product, and with our Red Bud’s, they are never disappointed.”

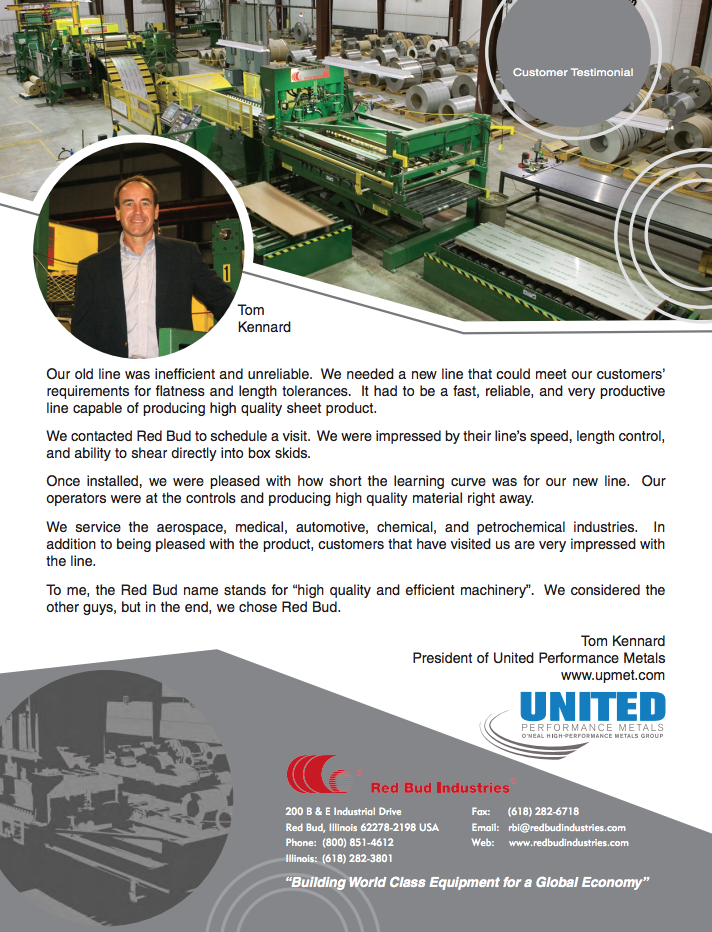

Read MoreTOM KENNARD, UNITED PERFORMANCE METALS

“Our old line was inefficient and unreliable. We needed a new line that could meet our customers’ requirements for flatness and length tolerances. It had to be a fast, reliable, and very productive line capable of producing high quality sheet product.

We contacted Red Bud to schedule a visit. We were impressed by their line’s speed, length control, and ability to shear directly into box skids.

Once installed, we were pleased with how short the learning curve was for our new line. Our operators were at the controls and producing high quality material right away.

We service the aerospace, medical, automotive, chemical, and petrochemical industries. In addition to being pleased with the product, customers that have visited us are very impressed with the line.

To me, the Red Bud name stands for “high quality and efficient machinery”. We considered the other guys, but in the end, we chose Red Bud.”

Read MoreJACQUES COUTURE, RUSSEL METALS INC.

“For accuracy, ease of installation, service reputation, and warranty, you can’t beat Red Bud.

We needed to increase our market share in the flat rolled market so we gave Red Bud a call. We decided to purchase a Red Bud Cut-To-Length Line because of its demonstrated cutting accuracy and ease of installation along with Red Bud’s five year warranty and their stellar service reputation. I’m pleased to report that our new Red Bud Line is extremely reliable and easy to use. We’re now able to offer a high quality finished product to our customers.”

Why did you buy the new line?

What did you hope to gain or accomplish?

“To increase our market share in the flat rolled segment. To gain flexibility on our cutting schedule.”

What markets do you or will you pursue with the line?

“We are pursuing the HVAC, appliance, and transportation market segments.”

Why did you buy the line from Red Bud?

“For its cutting accuracy, ease of installation, warranty, and service reputation.”

Did the line do everything you had hoped?

“Yes, the equipment is very reliable. The after sales service is excellent.”

Have you picked up new business as a direct result of the new line?

“Indeed, we are now able to offer a better finished product than our competition in most cases.”

List any additional comments relating to tolerances, efficiency, experience with installation and startup, or Red Bud personnel in general.

“The line upon delivery was almost 100% debugged which made the start up very easy. The technician that was on site during the final installation was excellent. The regular after sales follow up is appreciated.”

Read MoreTODD FOGEL, BASIC METALS, INC.

“When we purchased a new Cut-To-Length Line a few years ago, we went with Red Bud. Because of our positive experience and our satisfaction with the first line, we decided to go with them when we bought our new Slitter. We needed a line that would allow us to process wider coils, heavier gage material, and produce a higher quality product. We also wanted a line that was safer to operate and we liked the new innovations and safety features Red Bud had developed. Now that it is installed, the line does everything we had hoped. We have already picked up new business. Red Bud’s personnel are easy to work with and are very cooperative.”

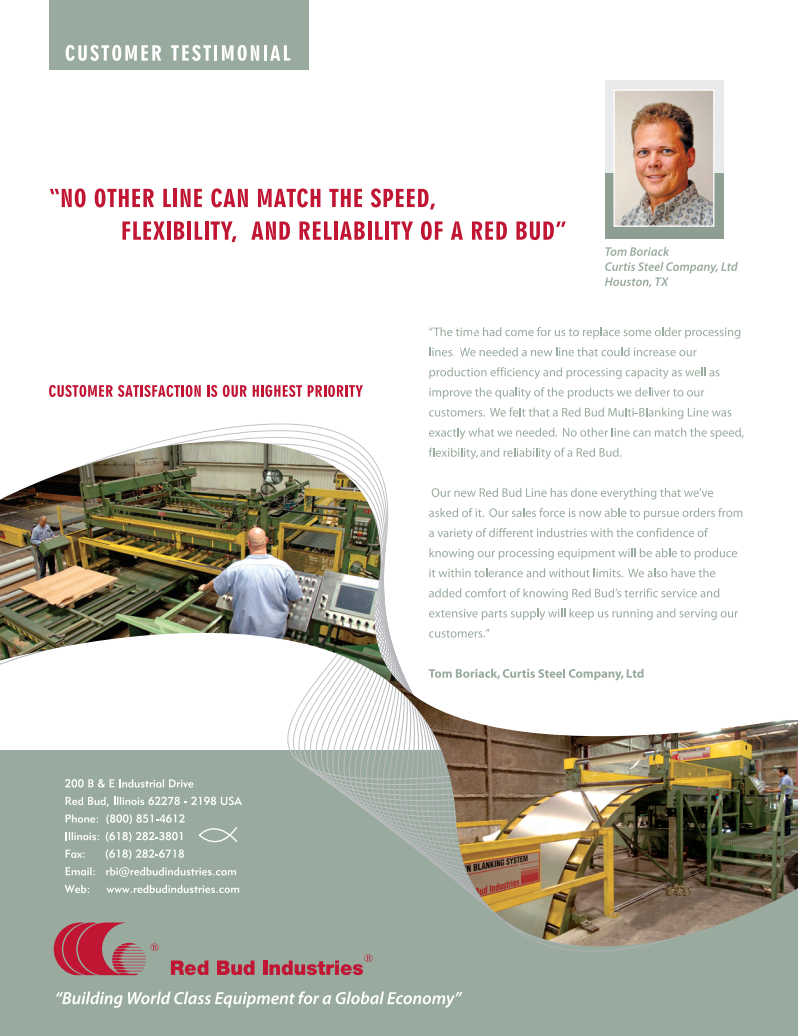

Read MoreTOM BORIACK, CURTIS STEEL COMPANY, LTD.

“The time had come for us to replace some older processing lines. We needed a new line that could increase our production efficiency and processing capacity as well as improve the quality of the products we deliver to our customers. We felt that a Red Bud Multi-Blanking Line was exactly what we needed. No other line can match the speed, flexibility, and reliability of a Red Bud.

Our new Red Bud Line has done everything that we’ve asked of it. Our sales force is now able to pursue orders from a variety of different industries with the confidence of knowing our processing equipment will be able to produce it within tolerance and without limits. We also have the added comfort of knowing Red Bud’s terrific service and extensive parts supply will keep us running and serving our customers.”

Read MoreDENNIS ERICKSON, RACO STEEL COMPANY

“Before purchasing our new line, we talked to many different people that owned or had experience with Red Bud Industries’ Lines. All were extremely satisfied. I also looked at competitor’s equipment but just felt they weren’t as well put together. I always felt Red Bud wasn’t trying to oversell their equipment. The line has done everything we have asked and more. It allows quick turnarounds for fast deliveries and produces tolerances closer than we thought possible. I have been very pleased with the performance and durability of the line. Our experience with Red Bud has been very good.”

Read MoreDON MORGAN, BLOCK STEEL

“Our new Red Bud Multi-Blanking Line produces dead flat blanks with ±.005″ (.127 mm) length and width tolerances on even the most surface critical exposed applications. The line performs as promised. With Red Bud’s multi-blanking technology and a Roller Leveler, we are able to produce the highest quality parts possible. From installation to service, everything was handled in an extremely professional manner.”

Read More