DALCO METALS

Desde 1973, Dalco Metals ha estado suministrando acero plano en toda la región central de E.U.

Con su nueva expansión, Dalco se vio en necesidad de una línea de procesamiento de bobinas que pudiera producir hojas de corte a medida de alta precisión, con una calidad sobresaliente de superficie. Red Bud Industries pudo proveerles una línea que cumpliera esos objetivos.

“La Línea de Red Bud nos ha permitido expandirnos a nuevos mercados y crecer nuestro territorio de mercadeo.”

-Bill Ring,

Presidente

Dalco Metals

FRIEDMAN INDUSTRIES, INC.

Friedman Industries is a flat-rolled and tubular service center headquartered in Longview, Texas. Their recently opened branch on SDI’s campus in Sinton, Texas, will allow them to reach new markets in the Southwest and West Coast of the United States and into Mexico with laser flat products coming off of their new Red Bud Industries 1.00” x 96” wide Heavy Gauge Cut-To-Length Line with Stretcher Leveling.

Red Bud checked all of the boxes that Friedman Industries was hoping to achieve with the purchase of their new equipment. Employee safety, value-added features, customer service, and in stock parts delivered the next day were the factors that swayed their decision. Most importantly, Friedman Industries wanted a partner that worked with them and kept the customer’s requests a priority.

«We wanted to align ourselves with a manufacturer that has the expertise and knowledge to build the line that we wanted. As Friedman Industries moves into other areas and explores other opportunities, Red Bud will be our first call when it comes to an equipment manufacturer.»

-Jonathan Holcomb,

VP of Sales and Purchasing

Friedman Industries

ALLIANCE STEEL

Alliance Steel is a flat-rolled service center

headquartered in Gary, Indiana. They also have offices in

Atlanta, Georgia, and Memphis, Tennessee.

Alliance Steel first partnered with Red Bud Industries in the early 2000s on a Multi-Blanking Line. Red Bud’s attention to detail and partnership on that first line birthed new opportunity for multiple pieces of equipment. As the steel industry evolved, Alliance Steel did too. They followed up with the purchase of a Red Bud Heavy Gauge Cut-To-Length Line with Stretcher Leveler. Most recently, their move into a new facility offered the opportunity to serve a new customer base looking for heavier gauge slit coils, but they needed a powerful Slitting Line to get the job done. Because of their confidence in Red Bud, Alliance Steel reached out to them to fulfill this need with a new .500″ (12 mm) Heavy Gauge Slitter.

«Red Bud has proven to be a great partner for Alliance Steel… They truly understand the value of production while coupling it with safety and I really, genuinely appreciate that.»

-Drew Gross, President

Alliance Steel

CHAMPAGNE METALS

Champagne Metals is an aluminum service center and processor that has been in business for 25 years. They are headquartered in Glenpool, Oklahoma, and also have facilities in Lebanon, Missouri, and Middlebury, Indiana. They serve all of North America, mostly in the automotive and industrial markets. Champagne Metals was looking to expand their capabilities, specifically in the blanking industry.

Since they do not process standard material day in and day out, Red Bud Industries’ ability to customize a coil processing line to their exact specifications and needs was very important to them. They also needed a vendor that they could trust to stand behind their machinery after the sale, and Red Bud delivered.

«Red Bud’s service has been fantastic. They have been veryresponsive anytime we call. Their hotline is there for any type of issue that we have, and they can log in and tell us what to do to it. . . We are absolutely satisfied with the way the line is running, and we would definitely look to do future business with Red Bud.»

-Burns Getchell, General Manager, Champagne Metals

Leer más Ver videoMIDWEST MATERIALS, INC.

MidWest Materials, Inc. is a third generation family-owned steel service center located in Perry, Ohio.

Over the past 70 years, MidWest Materials has grown and adapted to their customers’ demands of higher quality, close tolerance steel. Most recently, MidWest Materials began a search for a new stretch leveling system to increase their capacities and provide additional products. After talking to friends and competitors about their options, they decided to go with Red Bud Industries due to several major factors.

«We are extremely happy with the installation and the products coming off of the line. We expect that it will be a game-changer in providing heavy gauge, high-strength steel to the manufacturing world.»

-Brian D. Robbins, CEO

Leer más Ver videoWIELAND METAL SERVICES

Prior to the purchase of their Red Bud Industries Multi-Blanking Line, Wieland Metal Services used multiple coil processing lines to create their customers desired end product.

“We were able to condense two cut-to-length lines with the Red Bud Line. It opened up space in our facility and increased production and efficiency. If you are looking for a highly capable, safe machine, if you are looking for throughput, and a quality product, then I would truly recommend Red Bud.”

– Bhoopendra «Navin» Sukhraj

Leer más Ver videoCOIL STEEL PROCESSING

Red Bud’s Stretcher Leveler was exactly what Coil Steel Processing was looking for. Red Bud’s outstanding reputation for customer service and dedication to their customers made their choice easy. While the purchase of the new Cut-To-Length Line was going to expand their business, Coil Steel Processing knew that they also needed to improve the layout of their building.

“We could not be happier that we chose Red Bud. They have had a dramatic impact on our customers and our business.”

– Kevin Friedman, President

Leer más Ver videoMAGNA STAINLESS

“Red Bud stood out to Magna Stainless. Their service, support, and after sales service had a very good reputation. Red Bud is the leader in design and manufacture of Coil Processing Lines. They are able to offer an innovative, robust design that will always work and never let you down.”

-Nolan Mills, Operations Manager, Magna Stainless

Leer más Ver videoVALCOVNA PROFILOV

«One of the main advantages that Red Bud Industries gives us is 24/7 technical assistance that is on a very high level. Other companies in this business do not give us this high level of technical service. Based on our experience, we now decided to look for another cut-to-length line, of course, equipped with stretch level technology. And I am sure that Red Bud Industries will be one of the best suppliers of such equipment.»

-Vladimir Sumec, Valcovna Profilov

Leer más Ver videoBTH IMPORT STAL

BTH Import Stal has been an important supplier for the Polish steel industry for nearly three decades. They are among the largest domestic importers of stainless steel and have worked with the furniture, food, chemical, and other stainless steel industries.

Red Bud Industries was their first experience with coil steel processing. Red Bud’s advanced Multi-Blanking technology was important to BTH Import Stal in order to make 8 mults of stainless in one shearing cycle.

«We are processing 45,000 tons of stainless steel annually. Fortunately, Red Bud’s 24/7 hotline allows us to solve any problem that occurs within a few minutes. We are very satisfied with our purchase from Red Bud Industries, and I’m sure that our next purchase will also be from them.»

– Tomasz Kotarba, Member of the Board

Leer más Ver videoPETERSEN ALUMINUM CORPORATION

“What set Red Bud apart from the competition was their willingness to design a solution that worked for us. They were able to think outside of the box and create something that benefits us long-term”

[Mike Weis | Southeast Regional Manager | Petersen Aluminum Corporation]

Petersen Aluminum Corporation started in 1965 as a metal service center to the architectural metal industry. With ¬five locations across the United States, Petersen is an industry leader in providing factory-produced metal panels.

Petersen’s Acworth, Georgia, location currently has three Red Bud Lines in operation. Their newest, a Light Gauge Slitting Line, proved to be the solution for all of their facilities. The low-cost, small-footprint Slitting Line has been replicated at each of Petersen’s locations and has helped them capture market space and grow their capacity fivefold.

Leer más Ver videoLAPHAM-HICKEY STEEL

“The service and reliability of Red Bud’s steel processing lines are a known commodity for us.”

[Brian Hickey | President | Lapham-Hickey Steel]

Lapham-Hickey Steel is a fourth generation, family-run steel service center with a history dating back to 1926. Currently, they have 10 locations throughout the Midwest, Southeast, and Northeast. Processing coil, sheet, plate, long products, and fabrications, Lapham-Hickey servces every metal consuming industry.

Over 30 years of history with Red Bud Industries gave Lapham-Hickey ease of mind in purchasing their new 60″ Red Bud Slitting Line. Lapham-Hickey was looking for features that included safety, efficiency, and automation.

«The Red Bud Slitting Line help ensure our employees go home the same way they came in. From front to back of the line, there are automated features in place so that we don’t have to handle the steel. The capabilities of this line allow us to handle the full range of steel from .008″ up to .250″ narrow slit coils and high strength steel.»

Leer más Ver videoGREENPOINT METALS

“Red Bud’s service and support set them apart from the competition”

[Mike Caughell | Vice President | Greenpoint Metals]

Greenpoint Metals is a family-owned business that has been in operation for over 40 years. Located in Franklin, Ohio, they are a secondary processor of steel with a focus on sheet and coil. Greenpoint Metals is a customer-focused company that primarily serves the construction, mining, and other OE related businesses.

When Greenpoint Metals decided to offer sheet steel to their customers, they immediately began working with Red Bud. Though not initially planned, Greenpoint Metals added the Red Bud Stretcher Leveler to their line in order to better serve the needs of their customers.

«One of the reasons we went with Red Bud was their level of support. Not only were they phenomenal in helping us launch the line, but their collaboration in helping us design the line was a huge resource for Greenpoint Metals. Red Bud was able to specify every detail needed to produce a wide range of products for our growing customer base.»

Leer más Ver videoMISSISSIPPI STEEL PROCESSING

“Red Bud Industries is the leader in Stretcher Leveling Technology.”

[Mark Reynolds | Vice President | Mississippi Steel Processing]

Mississippi Steel Processing, located in Columbus, Mississippi, is a toll processor of flat rolled sheet and slit material. Open since 2011, they service a variety of industries including line pipe, automotive, and HVAC. Their 300,000 square foot building gives them the capability to store finished product as well as master stock.

When Mississippi Steel Processing’s customers demanded a flatter, straighter product, they began researching stretcher levelers to replace their outdated roller unit. Given a proven history with Red Bud Industries, their search for a new stretcher leveler did not last long.

“The Red Bud Industries Stretcher Leveler that we have is a game changer for us. It allows us to service a part of the market that we were not able to touch before its installation. In our first month of use, we exceeded our projected production by 2000 tons.”

Leer más Ver videoOILFIELD PIPE & SUPPLY (OPS) SALES COMPANY

“Our production has doubled since we made the investment in a Red Bud Slitting Line.”

[Adam Kimrey | Manager | OPS Sales Company]

Oilfield Pipe & Supply (OPS) Sales Company is a wholesale structural steel supplier that has been in business for over 35 years. They service road and bridge construction, piers, cattle working equipment, and the agricultural industry.

In 2017, OPS Sales purchased a pipe mill to produce small OD pipe for cattle fencing and gates. Initially, they used local toll processing companies for their slitting work. As their demand grew, OPS Sales decided to look into acquiring a slitting line of their own. After some research, Adam Kimrey advocates that Red Bud Industries’ family atmosphere and top-of-the-line product made their decision easy.

“At the end of the day, Red Bud Industries’ sophisticated Slitting Line does everything we hoped for and more. The biggest surprise and relief have been the exemplary service and support. The fact that they are a family owned company really fit what we were looking for.”

Leer más Ver videoCAMDEN YARDS STEEL

“Red Bud Industries enabled us to add out product mix, which in turn, allowed us to dramatically increase production and expand our market area.”

[Alan Kanoff | Co-Founder, President | Camden Yards Steel]

Camden Yards Steel, a flat rolled steel service center, started production in 2000 in Camden, New Jersey. With the ability to unload their own ships and up to 20 rail cars per day, they serve the entire Eastern seaboard from Maine to Florida and west to the Mississippi.

In 2018, Camden Yards Steel started research on installing a Stretcher Leveler and a Multi-Blanking Line. Ease of operation, reliability, and customer service were the deciding factors in choosing Red Bud Industries.

“We are able to run all of our products through the two pieces we purchased from Red Bud Industries. The consistency of the Red Bud Transforming Business quality is perfect. The Stretcher Leveler has enabled us to enter new markets. When we get ready to install our next piece of equipment in Columbia, South Carolina, it will be from Red Bud Industries.”

Leer más Ver videoVARSTEEL LTD.

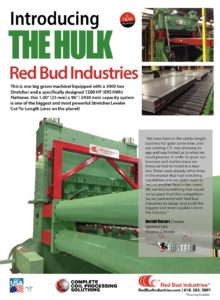

This is one big green machine! Equipped with a 3000 ton Stretcher and a specifically designed 1200 HP (895 KWh) Flattener, this 1.00” (25 mm) x 96” ( 2438 mm) capacity system is one of the biggest and most powerful Stretcher Leveler Cut-To-Length Lines on the planet!

”We have been in the cut-to-length business for quite some time, and our existing CTL was showing its age and was limited as to what we could process. In order to grow our business and market share we knew we had to invest in a new line. There were already other lines in the market that had stretching capabilities and we didn’t want to be just another face in the crowd. We wanted something that would set us apart from the competition. So, we partnered with Red Bud Industries to design and build the biggest and most capable Line in the industry.»

[Gerald Varzari | Owner | Varsteel Ltd.]

UNITED STEEL SUPPLY

“There is no one else making anything like the Red Bud Industries Light Gage Slitting Line.”

[Will Waldrip | Vice President | United Steel Supply]

United Steel Supply is a leading distributor and processor of steel products dedicated to the metal roofing and metal building industry in the United States. They warehouse and process bare and prepainted steel products for customers engaged in roll forming and other steel building applications.

United Steel Supply provides their customers with just-in-time delivery and transportation of their products. In most cases, they deliver products to their customers within 24 hours. Vice President Will Waldrip advocates that these services would not be possible without the Red Bud Industries Light Gage Slitting Line.

“Red Bud Industries has a product that allows us to focus on job completion, instead of throughput, which makes it very unique in this industry. With our growth at United Steel Supply, we have other facilities that will be needing slit lines, and I can assure you that the Red Bud Industries Light Gage Slitting Line will be at the top of our list.”

Leer más Ver videoCONKLIN METAL INDUSTRIES

“Red Bud Industries has helped us access new markets.”

[Smith Cooley | Vice President of Operations | Conklin Metal Industries]

Conklin Metal Industries has been a distributor of sheet metal, HVAC, and duct fabrication supplies for over 140 years. With 12 warehouses across the southeastern United States, they produce all of the metal needed for an installation of a complete residential or commercial HVAC system.

In 2017, Conklin Metal Industries began a search to improve their service and reliability on their steel processing. Safety, reliability, ease of use, and relationship with the vendor were the key factors in choosing Red Bud Industries. Conklin Metal’s new Red Bud Industries Light Gage, High Speed Blanking Line includes a Recoiler, beading capabilities, and an integrated Continuous Stacker.

“The purchase of the Red Bud Industries Line has helped improve productivity, enhance processes and procedures, and provide the best possible quality to our customers. We know we can guarantee uptime because we have 24/7 service and have ongoing employee training to improve efficiency.”

Leer más Ver videoRATNER STEEL SUPPLY 2019

“Red Bud Industries has been an integral part of our growth.”

[Dennis Szymanski | Vice President | Ratner Steel]

Ratner Steel Supply Company is an industry leader in providing the highest quality of both steel and customer service. With precise attention to detail, they ship over 500,000 tons of steel each year throughout the United States and Canada.

Since 1986, Ratner Steel has been a leading supplier to fabricators, OEMs, and regional service centers. With three locations in the United States, located in Roseville, MN; Portage, IN; and Osceola, AR, their state-of-the-art Stretcher Leveling and Cut-To-Length Equipment is able to supply customers with exactly what they need, where and when they need it.

“We bought our First Red Bud Industries Stretcher Leveler in 2008. Since then, we have installed two Stretcher Levelers in Portage, IN, and one in Osceola, AR. Our latest addition produces flat, stress free material up to 0.625” thick by 76” wide.”

Leer más Ver videoNATIONAL MATERIAL OF MEXICO

With Red Bud’s robust design, advanced technology, focus on safety, and terrific customer support, we knew partnering with Red Bud was the right choice. They delivered exactly what we needed.

[Luis Ignacio Villasenor, Director of Operations, National Material of Mexico]

NMM is a subsidiary of National Material L.P. which has a long history of quality and service dating back to 1946. Since its founding, National Material L.P. has grown to over 30 business units and is now one of the largest suppliers of steel in America. NMM is one of the largest Steel Service Centers in Mexico serving automotive, HVAC, home appliance, motor, and transformer manufacturers in Mexico.

When NMM started planning an expansion for its Monterrey facility, we needed a Slitting Line with specific capabilities and features able to handle the new generation of advanced high strength steel. Our search for a stronger, faster, and more capable Slitter led us to Red Bud Industries and their powerful line of equipment. Now that the line is operational, RBI technicians have been providing unparalleled 24/7 technical support, and we look forward to working with them in the future.

Leer más Ver videoPETERSEN ALUMINUM

Quality and Value that Satisfies

“Red Bud…has put us in position to grow our market share faster than the growth of the construction industry. We have been very pleased with the results.”

[Mike Petersen, CEO, Petersen Aluminum]

The first Mike Petersen had ever heard of Red Bud was at a NAAD board meeting many years ago. He heard a couple board members mention Red Bud’s Cut-To-Length Lines. Today, he owns a number of them himself. Over the last several years, they were experiencing growing demand across their product line and knew they also needed more slitting capacity. Hoping to find a high quality, high speed Slitter that met their needs was the challenge. Frankly, they didn’t think such a product existed. Enter Red Bud.

They bought and installed the first Red Bud Slitter in their Acworth, Georgia, plant and have since installed similar lines in each of their five plants. We currently have nine Red Bud Lines in total, and we have been very pleased with the results.

Leer másPACIFIC STEEL AND RECYCLING

When Pacific Steel and Recycling, a company with a 100+ year legacy, decided to expand into new markets, they put pencil to paper to run the numbers. With 40 locations in 9 states in the western United States, factors such as productivity, efficiency, logistics, and new market penetration all “penciled out” as the company researched and interviewed other companies to discover who they could partner with to maximize their investment. That search led to Red Bud Industries.

“We are very excited about our new 1/2″ x 96″ wide Red Bud Stretcher Leveler and expect to hit capacity very soon. As we continue to grow this line, we will absolutely look to work with Red Bud Industries in the future.”

Leer más Ver videoPVS-METALS

Our Red Bud Industries’ Stretcher Leveler is so much more than an important piece of equipment– it has transformed our business.

When PVS-Metals, a subsidiary of Owen Industries, decided to expand into new markets, they turned to Red Bud Industries. Their investment in this new, massive Stretcher Leveler allowed PVS to reach into an entirely new marketplace offering the latest in Coil Leveling Technology. With this new expansion and dramatically improved automation and capabilities, PVS can handle any project from design to delivery, start to finish.

Red Bud’s ongoing dedication to manufacturing the most innovative, world class equipment in the industry clearly separates Red Bud Industries from the rest.

Leer más Ver videoMAGIC COIL PRODUCTS

Red Bud has been outstanding in response to training our employees as well as dedication to our customers’ needs and requirements. Red Bud Industries is a world class organization.

Magic Coil Products needed much more than a clever illusion to keep steel processing customers happy. They needed Red Bud’s Multi-Blanking Line – a Cut-To-Length Line with slitting capabilities that makes it easy and efficient to produce a custom size part. Now Magic Coil Products can produce tight tolerance blanks faster and more accurately and that makes both Magic Coil and their customers happy. No sleight of hand or magic wand–just smart solutions from Red Bud Industries!

Leer más Ver videoMCNEILUS STEEL, INC.

The products and services we provide make our customers more competitive. That’s what Red Bud does for us as well.

Our sheet and plate customers are competitive if their steel is “table top” flat and stays that way after processing. We once thought that meant a temper mill, but the Stretcher Leveler is a far better value. Today, we operate four Red Bud Stretcher Leveler CTL Lines at three facilities. We can supply a customer from any one of these facilities knowing they will get the same consistent, high quality product from those lines; just as Red Bud delivers the same consistent, high quality technology and support to us, day-in and day-out, year-after-year.

Leer másMATANDY STEEL AND METAL PRODUCTS

When it comes to slitting technology, Red Bud is in a class by itself. And Red Bud support is world class too.

Ten years ago, we decided to enter the slitting business. We evaluated all slitter suppliers and saw that Red Bud clearly had the best technology – safety, set ups, throughput – they were top of the class. And no one else offered a 5 year warranty.

The decision to go with Red Bud has really paid off. The line is durable, accurate and Red Bud keeps us updated with new features they develop that make it perform even better. And you can’t ask for more responsive support. Anyone looking for a slitter would do well to talk to Red Bud.

Leer másRATNER STEEL SUPPLY

Customers choose us because our product is predictable, reliable, and repeatable. Same reasons we choose Red Bud.

We sell high quality cut sheet and plate our customers count on to stay at after lasering, forming, or whatever they do with it. Red Bud has the best technology for that, but execution really sets them apart. We operate two Red Bud Stretcher Leveler CTL Lines at our original facility, and decided to build a greenfield service center based around this advanced .500” Stretcher Leveler CTL Plate Line. We cut coil the same day we opened, and within just a few weeks, we were running 12 hours a day, 7 days a week, thanks to predictable, reliable, repeatable Red Bud support.

Leer más Ver videoMCNEILUS STEEL, INC.

Red Bud’s technology gave us a clear competitive advantage. Their service helps us maintain it.

At McNeilus Steel, we succeed by adapting to our customers needs. They needed ‘stay flat’ steel blanks, so we invested in a Red Bud Blanking Line with Stretcher Leveling. Our customers were delighted with the product, but also wanted it in heavier gage. We thought we‘d have to buy a temper mill, but Red Bud adapted to our needs and produced the first-ever .500” Stretcher Leveler CTL Plate Line. We were so pleased we bought two more. Not just because of the technology, but also because Red Bud supports us so well. They’re a customer first company.

Leer másHIGH STEEL SERVICE CENTER LLC

Red Bud equipment and service gives us a competitive advantage our customers prefer.

The Dependability Difference® is High Steel Service Center’s commitment to provide value-added services and product innovations to support our customer’s success. Red Bud Industries plays a crucial role in meeting that commitment. Our HIGHSL® – Panel Flat that Stays Flat, 100% stress-free sheet and plate product is produced on a Red Bud Stretcher Leveler. We produce carbon, stainless, and aluminum leveled sheet and plate, multi-cut precision blanks, and slit coil – all on Red Bud equipment. Red Bud accuracy, reliability, and automation helps us deliver the highest quality material, on time, to keep our customers competitive.

Leer másPHOENIX METALS

Red Bud’s performance and reliability have been key to our growth. That goes for their equipment and their service.

I spec’d, bought and installed this Red Bud Multi-Blanking Line 15 years ago. The product coming off was of such quality and accuracy, it helped us win customers. Since then, we’ve added 7 more Red Bud Lines.

At Phoenix Metals, we are committed to fast turnaround of orders and we’ve built an infrastructure that allows us to do it. Our Red Bud Lines are dependable and they change over fast – they are key to our ability to respond. Just as important is Red Bud’s support. Many suppliers claim ‘24/7’ support. Red Bud actually delivers it.

Leer másMACSTEEL SERVICE CENTRES SA

“We wanted to buy a Stretcher in order to improve our market share and differentiate our products from the rest of the market. We knew it would allow us to achieve unsurpassed flatness and eliminate spring back. After looking at a number of different manufacturers, we decided to go with Red Bud. They already had a lot of experience with stretcher leveling and had a proven track record.

Now that the Stretcher is in operation, we are very happy with our decision. Our clients have reacted very well to the product we are able to produce. Our volumes have definitely increased. What stood out to us was Red Bud’s total commitment to our satisfaction and the responsiveness of their team. Our experience with Red Bud was very good. They produce a quality machine and stand behind their products.”

Leer másPAUL BATTY, MIDWAY METALS

“We were looking for a new line to help better position ourselves in the market. We decided to go with Red Bud because of their reputation, service, and innovative designs. We felt their stretcher leveling technology would give us the opportunity to offer our customers a superior level of flatness. Now that the line is in, I have to say it performs as advertised. We have people that ask for our product due to the flatness we can produce and some customers have already told us they will not order from anywhere else.”

Leer más