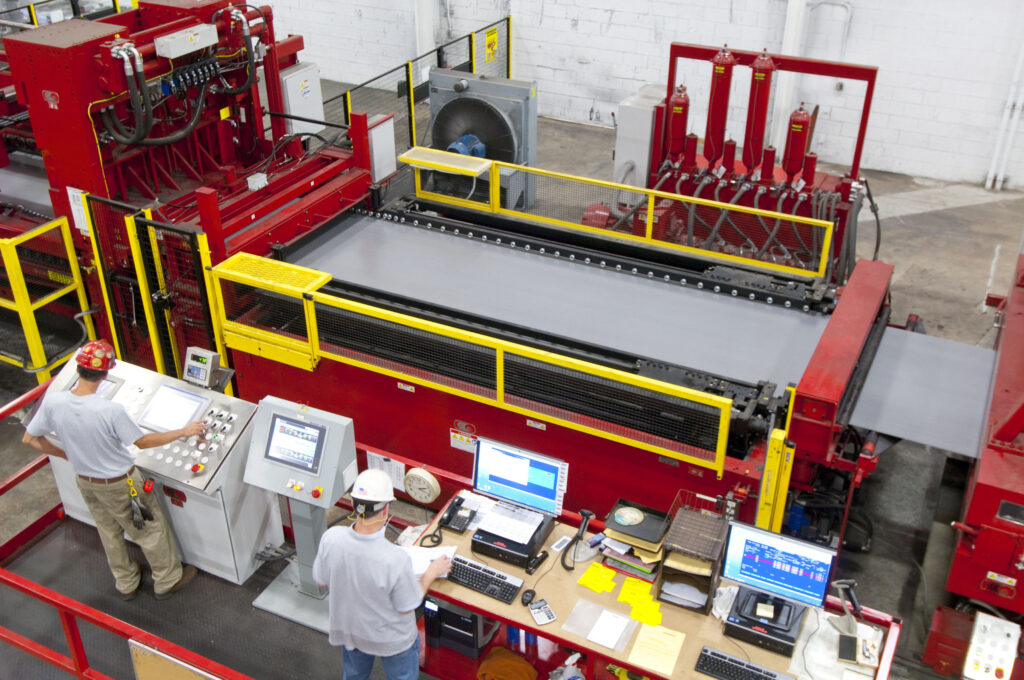

Best Grip Feed for Repeatable Length Tolerance in the Industry

Innovative Grip Feed System

Over the years, Red Bud’s Blanking Technology has set the standard by which other systems are measured. Today, our systems continue to redefine the blanking industry. The key to our Cut-To-Length Line/Blanking Line is our Grip Feed Measuring System. Our unique system produces ±.005” (0.127 mm) length tolerances on a single stroke regardless of part length, speed, or material thickness.

Unsurpassed Tolerances & Speed

Our Grip Feed System can operate at production speeds up to 275 FPM

(84 m/min) in “Standard Mode” and 400 FPM (122 m/min) in Dual Action Mode. Our exclusive Control System can improve tolerances by automatically adjusting the Grip Feed for cambered material. The Grip Feed has specially designed non-marking grippers that maintain a positive grip on the material at all times. In addition to preventing slippage, the grippers automatically square the strip as it is fed into the Shear. The results are unsurpassed length and squareness tolerances.

All Gauge Grip Feeds

When used as part of our Heavy Gauge Lines, the Grip Feed allows material up to .375″ (9.5 mm) thick to run in a deep loop. Because our Grip Feeds maintain a positive grip on the material at all times, accuracy is not affected by the gauge of material being processed.

Our Grip Feeds:

- Feature the best “real world” cut to length tolerances in the industry regardless of material width or thickness

- Can process surface critical material without marking

- Produce higher line speeds without experiencing material slippage

- Include a 5 Year Warranty with lifetime access to our 24/7 “Service Hotline”

Grip Feed Systems Support

When you select Red Bud Industries’ Grip Feed System, you will gain access to 24/7 support. We know how important it is to have your machinery up and running at all times. Many other manufactures fall short when it comes to continued support, education and maintenance. Call +1 618 282 3801 today to experience the difference of working with a company that is passionate about building the best Grip Feed Systems, as well as the best relationships.