The Latest in Coil Processing Technology

Continuous Stacking System

Red Bud Industries offers unparalleled production capabilities with our Continuous Stacking System. This advanced Single Stacking System performs like a Dual Stacker without the cost or need for the extra floor space. This automated system reduces down time between skid changes to as little as six (6) seconds. Once a pallet is finished, the Stack Table lowers, and a set of temporary support arms move into position. Once in position, the line restarts and parts are stacked on the temporary arms. While the line is running, the finished stack is removed. An empty pallet is then automatically loaded and raised into position. Once the pallet is in position, the temporary arms retract, and the material is automatically lowered onto the new skid. Additionally, this sequence of events can be automated to the point where the operators’ only responsibilities are to ensure there are empty pallets on the Pallet Loading System, and the finished packs are removed from the line.

Magazine Pallet Loading System

Red Bud Industries offers advanced pallet prestaging and loading automation with a Magazine Pallet Loading System. This unit works in concert with our Pallet Loading System. The Magazine Pallet Loading System can be preloaded and store multiple skids at a time. When required, the system will automatically dispense the next skid and lower it directly onto the Pallet Loading System. As a result, the line always has pallets loaded and ready for use.

Coil Prep Area

Proper coil management is crucial to keep your coil line running with minimal downtime, and a crucial part of coil management is Coil Prep. Our Coil Prep Area allows you to “pre-prep” coils before they are loaded onto the line. The Coil Prep Area incorporates powered coil rotation rolls that allow the operator to turn the coil so the tongue is down. Once in this position, banding and any protective paper covering can be safely removed. These operations can be completed while the line is running and prevents the line from waiting for coils.

Quick Change Shear Blades

Changing out dull blades on a Shear can be a very labor intensive and time-consuming task. To address this unavoidable maintenance task, Red Bud Industries offers a Quick Change Knife Cassette System. Mobile Cassette Exchange Carts are used to remove the dull knives from the Shear and insert a fresh set of Shear blades. This greatly reduces the time required for blade maintenance on the Shear.

Lift Type Discharge Roller Conveyors

Getting finished pallets away from your coil line and keeping your exit discharge conveyors open to receive additional pallets is key to increasing uptime and production. To address this, Red Bud Industries offers Lift Type Discharge Roller Conveyors. These Conveyors include supports to help facilitate banding and the removal of finished stacks using a sheet lifter or fork truck. Once the stack is in position, the rollers lower, which allows the material to be held above the Conveyor on the supports. The system also allows parts to be stacked directly on the Roller Conveyors and runners to be introduced to the stack after being discharged.

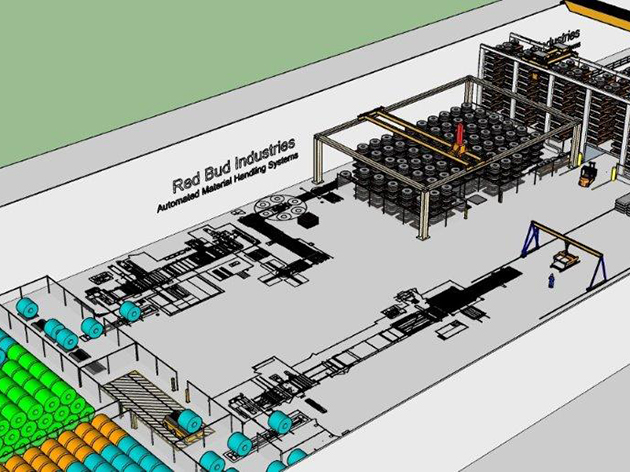

Automated Material Handling Systems

Red Bud Industries is now offering Automated Cranes for coil storage and retrieval, as well as Slit Coil and Sheet/Blank Storage Systems. These systems will reduce your labor cost, create a safer working environment, and also significantly reduce the footprint of the building.

Whether you are looking at a new facility or you just want to improve an existing site, we can work with you to lay out the best system for your application. Scaled drawings can be provided to give the customer a clear vision of how the operation will look and function. These systems can be integrated with Red Bud Industries’ Coil Processing Equipment to allow for better scheduling and improved productivity. Integrating an Automatic Material Handling System with state-of-the-art Coil Processing Equipment can truly create a facility that is designed for the next generation.

Red Bud Industries Offers Automatic Coil Loading System

Red Bud Industries offers a fully automated Coil Prestage & Load System for their Heavy Gauge Coil Processing Lines. This system automatically advances prestaged coils and loads them onto a Dual Stub Uncoiler. The advanced system is comprised of an in-line Coil Prestaging System, integrated Coil Car, and Dual Stub Uncoiler. These components operate in concert to eliminate the need for operator attention or intervention when loading coils. With the push of one button, the Coil Prestage & Load System’s integrated Coil Car retrieves the coil to be processed. The system will then measure the outside and inside diameters of the coil. After measuring, the Coil Car will position and raise the coil as required automatically for loading onto the line’s Uncoiler. The Dual Mandrel Uncoiler will then spear the coil and center it automatically on the line. This sequence of events takes place unattended by the line’s operator.

The Coil Prestage & Load System can also incorporate a Coil Reject Station. Unlike traditional In-Line Coil Prestaging Systems which have no means of their own to change the sequence in which coils are to be processed, this supplementary coil staging area allows the process order of the coils to be changed when required. It also allows for partially processed coils to be removed and stored offline eliminating the need for an overhead crane to remove a coil before the next coil can be processed. This allows for quick changeover to the next coil to be processed.

Red Bud Industries Offers A Rotating Brush Dust Collection System

Red Bud Industries offers a Rotating Brush Dust Collection System. In the past, many companies have offered a variety of vacuum systems to remove both scale and hot roll dust from the surface of the strip as it is processed in a Coil Line. These basic vacuum systems relied on the power of the vacuum alone to remove the dust and debris from the material. However, after vacuuming, a significant amount of scale and dust remained on the surface of the material. This is because the debris on your material acts just like the dust on your car. There is a magnetic attraction between the dust and debris and the metal surface. Have you ever noticed how, even at highway speeds, not all the dust is blown off the surface of your car? So too after vacuuming, not all the loose scale and hot roll dust have been removed from your material. To improve the cleaning process, Red Bud Industries has developed a combination Rotating Brush Dust Collection System. This advanced system utilizes a pair of non-marking upper and lower rotating brushes in concert with a vacuum to agitate the surface of the material and remove a much larger amount of dust and debris from both sides of the strip. This will greatly reduce the amount of dust and dirt spread around your Coil Line and your plant. To increase brush life, the upper and lower brushes alternately move from side to side as they rotate so the brush wears more evenly. The Rotating Brush Dust Collection Unit is available on new lines and can also be retrofitted onto existing lines as well.

Red Bud Offers Dual Mandrel Turret Recoiler

Red Bud Industries offers a Dual Mandrel Turret Recoiler for use in their Coil-To-Coil Slitting Lines. Known for building high capacity process lines that set up and changeover quickly, the Dual Mandrel Turret Recoiler was the next logical improvement to their existing product line. By incorporating two complete mandrels, overarms, and coil pushers on a single swivel base, end users can rotate the Recoiler and restart the line quickly. The previously slit coils are then removed and conveyed to a Packaging System while the line is running.

Red Bud’s Pop Top Precision Straightener Handles 1.00″

Red Bud Industries expands the capacity of its heavy gauge line of equipment by offering a 1.00″ (25 mm) precision backed up Straightener with the unique Pop Top design. This feature allows access to the Straightener work rolls in addition to the work roll backups. This design is especially well suited to processing hot rolled material where the build up of dust and debris is inherent in the material type. The new Straightener is capable of processing strip up to 1.00″ (25 mm) thick by 96″ (2438 mm) wide.